1. Chemical composition

| C | 0.38-0.43% | Cr | 0.70-0.90% |

| Si | 0.15-0.35% | Mo | 0.20-0.30% |

| Mn | 0.60-0.80% | Ni | 1.65-2.00% |

| P | ≤0.025% | S | ≤0.025% |

2. Equivalent Steel Grade

| DIN | 1.6511/1.6563 |

| ASTM A29 | 4340 |

| JIS | SCM439 |

| BS | 816M40 |

| GB | 40CrNiMoA |

| EN 10263 | 41NiCrMo 7-3-2 |

| NF | 40NCD3 |

| ISO 683 | 36CrNiMo4 |

| GNS | G43400 |

3. Q+T Properties

| Tensile Strength | σb (MPa):≥900(100) |

| Yield Strength | σs (MPa):≥835(85) |

| Elongation | δ5 (%):≥12 |

| Reduction | ψ (%):≥55 |

| Impact Energy | Akv (J):≥78 |

| Impact Toughness | αkv (J/cm2):≥98(10) |

| Annealed Hardness | ≤269HB |

4. Surface Treatment

Plate: Origin Black, Orign cold rolled bright, Machined, Grinded

Bar: Origin Black, Orign cold rolled(drawn) bright, Turned, Peeled, Grinded

5. Size

Round bar: Diameter(mm) Max 800mm; Length(mm) Max 12000mm.

Plate: Thickness(mm) Max 800mm; Width(mm) Max 2300mm; Length(mm) Max 12000mm.

Condition: Cold rolled(drawn)≤50mm, Hot rolled≤12-250mm, Hot forged≥50mm.(Thickness/Diameter)

6. Heat Treatment

1) Forging

Preheat the steel carefully, then raise the temperature to 1150-1210°C for forging. Do not forge below 850°C. 4340 has good forging characteristics but care must be taken when cooling as the steel shows susceptibility to cracking. Cooling in ash or lime after forging is recommended

2)Annealing

Heat the steel slowly to 800-860°C and allow enough time for the steel to be thoroughly heated. Cool slowly in the furnace.

3)Stress Relieving

When components are heavily machined, ground or otherwise subject to cold work, stress relieving will be beneficial prior to hardening.

4)Hardening

4340 steel is usually supplied ready heat treated. If further heat treatment is required annealed 4340 should be heated slowly to 830-865°C and after adequate soaking at this temperature quench in oil. Temper as soon as the steel reaches room temperature.

5)Tempering

Heat the steel carefully to a suitable temperature selected by reference to a tempering chart or table, soak at the temperature for 2 hours per 25mm of section, then allow to cool in air.

7. Charateristics

4340 steel offers toughness and high strength in the heat treated condition, with good fatigue strength. Available in round bar 4340 is available fully certified and suitable for applications requiring a quality high tensile alloy steel. AISI 4340 is commonly supplied quenched and tempered with a hardness of between 24 to 29HRc

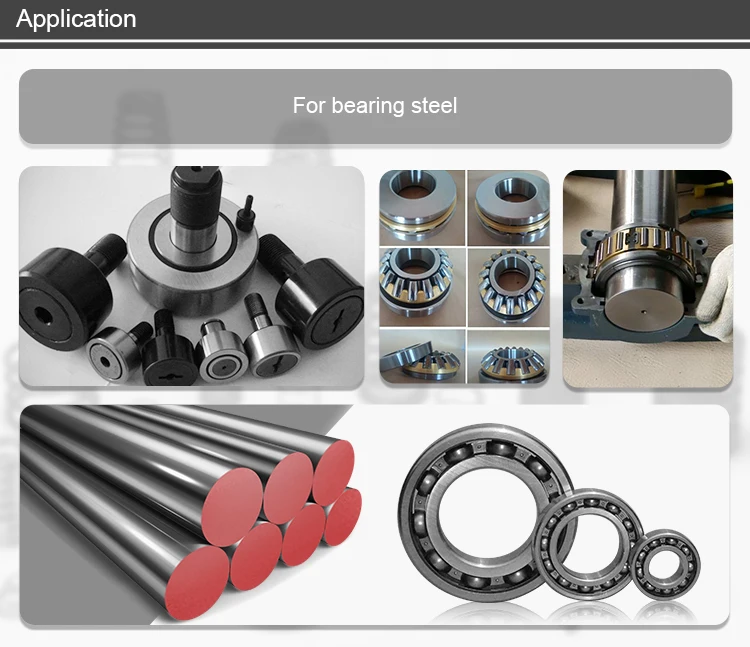

8. Applications

This grade of steel is suited for shock loading or stress concentration applications such as shafts, gears, bolts, nuts, pins and couplings.