Motorcycle crankshaft:

The working principle of the motorcycle crankshaft

The crankshaft of a motorcycle is a component that ignites the gasoline in the engine. The gasoline combustion work drives the live race down, and then drives the crankshaft to rotate. It also depends on the inertia of the crankshaft to maintain operation when it is not ignited. As long as the engine is started, the crankshaft will continue to rotate, and drive the magneto to generate electricity, charge the battery and use it for power devices in the car. If the gear does not go, it means pinch-clutch (hand-clutched models) or idling (auto-clutch models such as pedals or curved beams). At this time, the crankshaft is still rotating. Bending beam or pedal) the car will not go, the resistance of the engine is slightly increased, but the effect is very small, and the engine speed in neutral is the same.

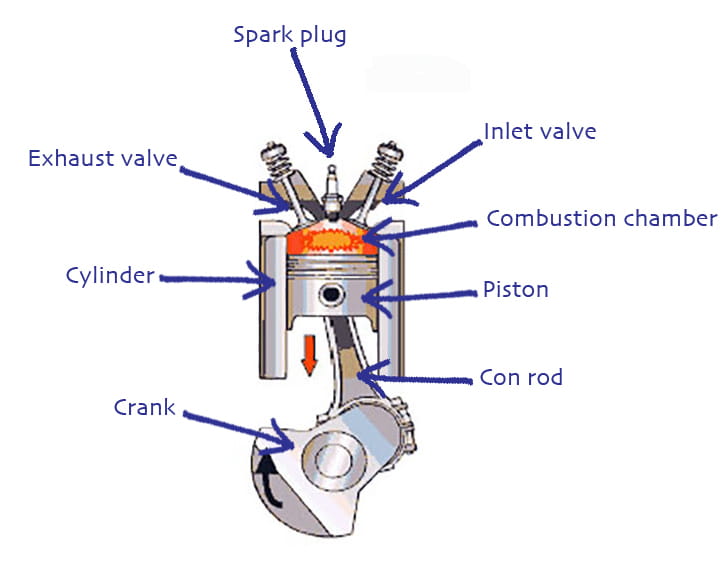

The motorcycle crankshaft is one of the most important parts in the internal combustion engine. It connects the piston, connecting rod and camshaft. Its main function is to convert the reciprocating motion of the piston into the rotational motion of the output shaft, thereby driving the operation of the motorcycle.

The crankshaft consists of multiple cranks, each of which is connected to a piston and a connecting rod. When the piston moves up and down in the cylinder, the connecting rod drives the crank to rotate, and finally converts the reciprocating motion of the piston into the rotational motion of the output shaft. This motion conversion method allows the motorcycle to run smoothly and provides enough power to drive the vehicle.

The design and manufacture of the crankshaft need to take into account many factors, such as strength, weight, thermal expansion coefficient, noise and fuel consumption. Modern motorcycle manufacturers usually use high-performance alloy materials to manufacture crankshafts to improve their performance and durability.