Core characteristics

Material advantages

- Corrosion resistance: Contains 18%~20% chromium and 8%~10.5% nickel. The surface passivation film can resist acid and alkali corrosion and is suitable for humid/chemical environments210.

Mechanical properties: Tensile strength ≥520MPa, yield strength ≥205MPa, elongation ≥40%, with both high strength and processing plasticity214.

Temperature range: Stable performance within -196°C to 800°C, no heat treatment hardening

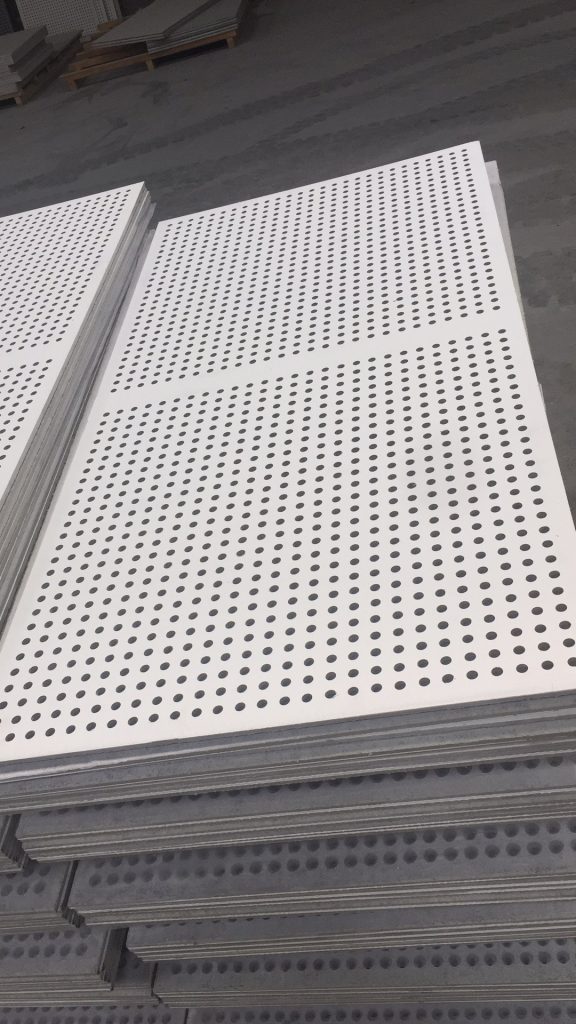

- Perforated plate process parameters

Core characteristics Material advantages 1. Corrosion resistance: Contains 18%~20% chromium and 8%~10.5% nickel. The surface passivation film can resist acid and alkali corrosion and is suitable for humid/chemical environments210. Mechanical properties: Tensile strength ≥520MPa, yield strength ≥205MPa, elongation ≥40%, with both high strength and processing plasticity214. Temperature range: Stable performance within -196°C to 800°C, no heat treatment hardening

2. Perforated plate process parameters star_border

| ITEMS | Rang | Describe |

|---|---|---|

| Thickness | 0.2–20mm | Cold rolled (0.02–4mm)Or Hot rolled(4.5–100mm) |

| Hole Size | 0.5–200mm | Supports customization of round holes, square holes, diamond holes, etc |

| Hole design | Uniform array/artistic pattern | Precision machining by CNC punching machine, smooth edges without burrs |

- Core application scenarios

Industrial field

Filtration and screening: mine screens, granary ventilation nets (such as 60 mesh perforated plates), mechanical protective covers.

Environmental protection equipment: wind and dust suppression nets, sound barrier sound absorption layer (used in combination with sound-absorbing cotton).

Architecture and decoration

Curtain wall/partition: light-transmitting but not shadow-transmitting, optimizing space lighting; hole design reduces sunlight glare.

Safety protection: balcony anti-fall nets, anti-slip pedals (enhanced surface friction).

Life and special uses

Household items: decorative nets, perforated boards, kitchen utensils (corrosion-resistant and easy to clean).

Medical/aviation: surgical instrument brackets (biocompatible), aircraft lightweight components (aluminum alloy alternatives)

Customization points

Clearly define the requirements for aperture, hole spacing, thickness and tensile strength, such as the common specification of “1.0mm thickness + 5mm aperture”.

Surface treatment: Mirror or brushed process is preferred to improve stain resistance and aesthetics