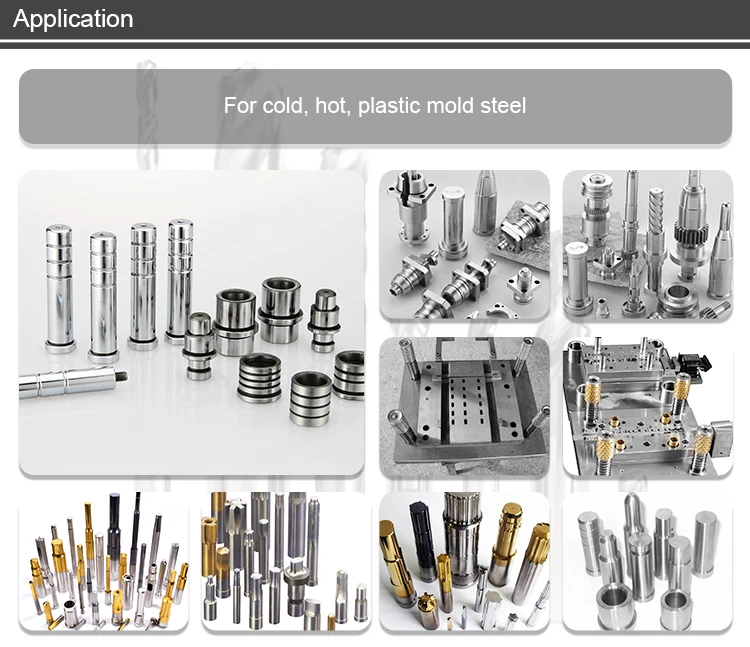

Applications:

H13 tool steels are suitable for forming extrusion dies.

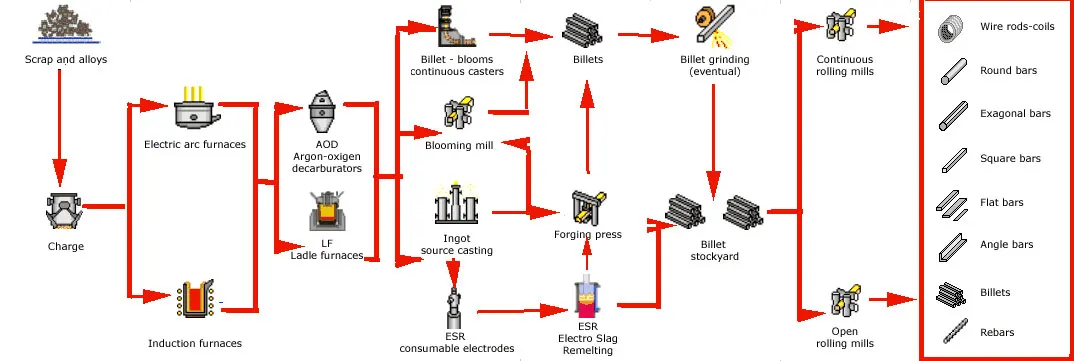

Steel Machining:

Chemical composition(%)

| Grade | C | Mn | P Max | S Max | Si | Cr | V | Mo |

| H13 Alloy tool steel | 0.32 to 0.45 | 0.20 to 0.60 | 0.030 | 0.030 | 0.80-1.25 | 4.75 to 5.50 | 0.80to 1.20 | 1.10 to 1.75 |

| Grade | C | Mn | P | S | Si | Cr | V | Mo |

| 1.2344 | 0.32-0.45 | 0.20-0.60 | 0.030max | 0.030max | 0.80-1.25 | 4.75-5.5 | 0.80-1.2 | 1.10-1.75 |

Hardeness

| Type | Annealed Max BHN | Cold Drawn MaxBHN |

| H13 | 235 | 262 |

| Steel Grade | AISI H13/DIN 1.2344/JIS SKD61 |

| Size & Dimension | Diameter: 600 mm(Max) |

| Surface treatment | Black/Peeling/Polishing/Machined |

| HBW | ≤235 |

| Technique | Cold/Hot rolled, Cold-Drawn or Hot Forged |

| Heat Treatment | Annealed; Quenched; Tempered |

| Delivery Condition | Hot Rolled or Forged/Peeled or Black Surface/Annealed or QT |

| Test | SGS/UT100%/Elements Testing |

| Certificate | ISO/Mill Certificate |

CUSTOMER FEEDBACK